Microfiber

Microfiber

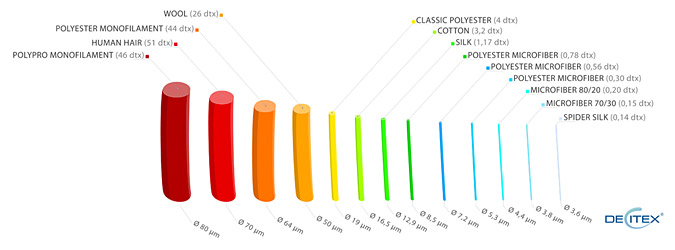

Microfiber comes to the fore (Decitex defines microfiber). DECITEX is the name of our company but is also a textile measurement which explains the titre (linear mass ) of a strand.

The titre in Decitex (dTx) represents the weight in grammes of 10 km of thread. We speak of microfiber when the titre of the thread is less than 1 decitex.

Examples:

- A thread of 0,2 dtx = 10 km of threads weighing 0,2 g |-| their titre is less than 1 dtx => so they’re microfibers

- A thread of 4 dtx = 10 Km of threads weighing 4g |-| their titre is greater than 1 dtx => so they’re not microfibers

The table below gives an indication of the diameter of thread thickness for different structures.

The fineness of microfiber threads makes it possible to increase the density of cleaning textiles in an extraordinary way: 1 dishcloth MINI 320 contains 1300 km of microfiber… put end to end, you could circle the world with 30 MINI 320 cloths!

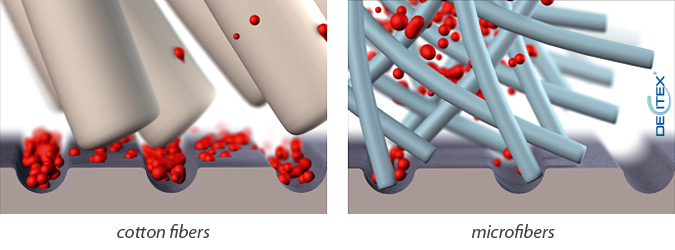

Thanks to their thinness and density, Decitex microfiber products easily cope with soiling just by rubbing (mechanical force) and then absorbing it deeply into the spaces created between the fibres (capillary action).

Mechanical force

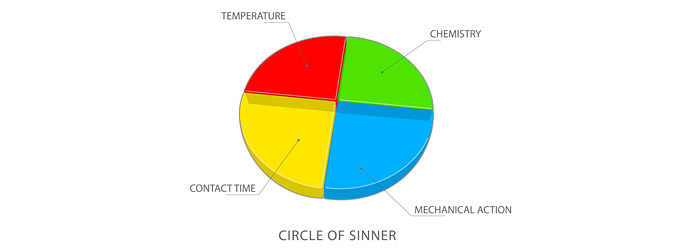

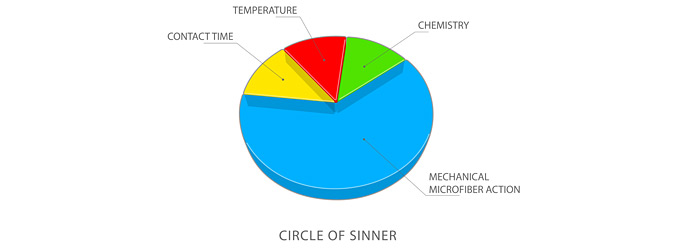

The Sinner Circle defines the 4 factors that are indispensable to a good cleaning: chemical action, mechanical action, temperature and time of action. Reduction of one of these implies the need to compensate by one or several of the others.

Following this principle, increasing the mechanical factor implies reducing the chemical factor and the contact time and related temperature. This is the targeted aim of the Decitex microfiber product range.

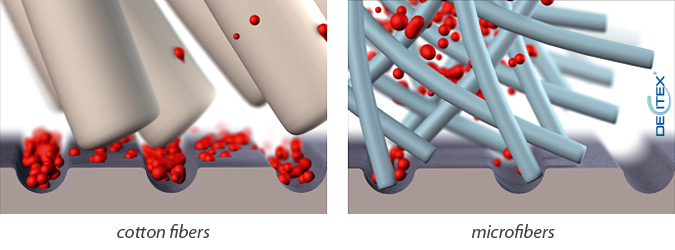

The thinness of the microfiber thread increases the mechanical force on the surface in two ways:

- Microfiber can seek out dirt in the tiniest surface irregularities

- With one wipe, the high density per cm² allows the simultaneous action of thousands of microfibers on the same surface point

Just going from ordinary fibre to microfiber, the textile has hugely increased its mechanical ability to pick up surface dirt.

Its impact on the need for chemicals is therefore immediate and the Sinner Circle can be changed to read:

It’s therefore essential to ensure that the microfiber part of the product is maximised. It’s better to choose a product with 90% microfiber in 0,78 dtx than to have just 50% microfiber in 0,20 dtx.

Capillary force

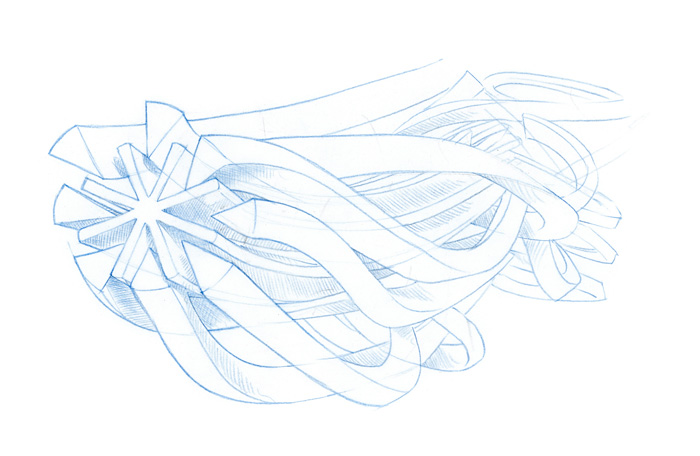

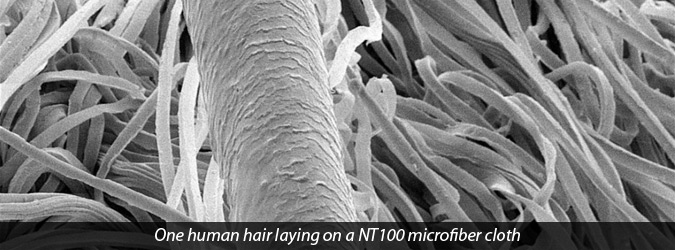

A single hair placed on a microfiber dishcloth NT100.

The above microscopic view shows the extreme density of the network of free spaces formed by the weaving of the microfibers. It’s what we call the capillary network.

The capillary network gives to microfiber its ability to absorb water, liquids and small particules (surface dirt).

The network’s density allows very rapid liquid absorption, rather like a sugar cube plunged into coffee.

The capillary force of microfiber has the double advantage of being able to easily absorb liquids but also to free them onto the surface when required. It‘s thanks to capillary action that Decitex microfiber mops absorb the solution in the bucket and distribute it evenly on the floor.

Electrostatic force

All the materials are composed of atoms and each atom is composed of a positive charged nucleus, around which several negative electrons gravitate. An atom that loses one or several electrons has therefore a positive charge. On the other hand, an atom that gains one or several electrons has a negative charge and is called an « ion ». At rest, an atom has a neutral charge.

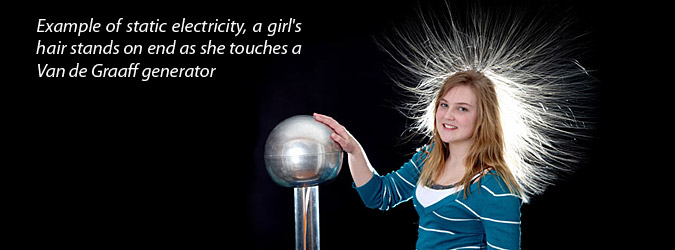

Static electricity is a surface phenomenon that is generated when two or more surfaces come into contact and are then separated (by rubbing for example). An imbalance is produced during which negative electrons are transmitted from one atom to another. The power of the charge (the field force) depends on several factors: the material; its physical and electrical properties, its temperature, the ambient humidity of the air and the power and speed of the separation.

Synthetic fibres like polyester, polyamide or the polypropylenes used in the make-up of microfiber products are perfect for developing a static charge by rubbing. So the surrounding dust is easily attracted by the static charge. So it is that microfiber products become excellent dust collectors by simple dry rubbing. Dusting becomes child’s play.

On the other hand, on contact with water, the surface becomes a semi-conductor and loses its static charge. So, once wet, there’s no electrostatic force!

Polyester

Polyester doesn’t absorb water: it is hydrophobic.

But polyester adores grease: it’s lipophilic.

Polyester resists both temperature and chemical attack.

|

|

POLYESTER |

POLYAMIDE |

POLYPROPYLENE |

|

Fusion point in °C |

225-240 °C |

215 - 260 °C |

165 - 175 °C |

|

Short term heat resistance in °C |

170 °C |

130 °C |

80 °C |

|

Resistance to alkalis |

Good |

Good |

Excellent |

|

Resistance to acids |

Good |

Good |

Excellent |

|

Resistance to petroleum products |

Excellent |

Good |

Excellent |

|

Résistance to bleach - solvants |

Excellent |

Discolours. Degrades in inorganic acids and oxidants. Insoluble in organic solvants |

Excellent |

These characteristics are an ideal combination to combat the problems encountered by professionals and increase the effectiveness of microfiber products. For floor cleaning, using 100% polyester microfibers is ideal. It will make it possible to spread the water evenly over the surface (thanks to the capillary network created by the microfibers) and to clean and degrease the surface by absorbing it into the centre of the polyester without spreading it around.

Urban myths dispelled

- The wetter it is, the better it cleans!

- Microfibers cannot withstand bleach!

- Buying cheaper equipment is more profitable!

- Only chemicals can remove bacteria

- If it's more resistant it's better for the planet

- 100% microfiber is better!

- The thinner the thread, the more efficient!

- Some microfibers scratch, others absorb!

The wetter it is, the better it cleans!

FALSE.

When cotton textiles (mops, swabs...) were still in common use, they were used to deposit a chemical solution on floors so this could act on the dirt. The chemical solution was the main cleaning element.

Those days are over; microfibers textiles have appeared that put the fibre at the heart of the washing action, making it the main detergent before chemicals. Chemicals are now used on specific stains and to provide a fragrance.

The mechanical and capillary action of textiles made from microfibers help lift the dirt and capture it at the heart of the fibres. It is therefore no longer necessary to wet as much, as in most cases, the microfiber alone is enough and can be used with water only.

Extra tip

The performance of the microfiber allows for limited water consumption and drying times are greatly improved as a consequence.

Microfibers cannot withstand bleach!

TRUE but there are exceptions.

Bleach is an anti-bacterial chemical that is corrosive for textile; it shortens its life by destroying fibres and making holes.

Most market players state that the life is guaranteed under certain standard conditions of use: including no bleach, no softener, compliance with washing protocols...

Decitex goes against this practice with Dispomop® 3D by allowing the use of bleach with a guaranteed life cycle of 50 washes.

Litigations connected to the use of bleach no longer lead to claims, DECITEX offer its customers a product that is more than ever "easy care".

Buying cheaper equipment is more profitable!

NOT NECESSARILY!

There are 2 categories of costs linked to the use of textile microfibers:

- The purchase cost for buying the microfibers

- The maintenance cost for washing the microfibers.

For a standard microfiber mop: the maintenance cost is on average 5 times the purchase cost. For a microfiber dishcloth, the ratio is around 3.

It is therefore a priority to optimise the maintenance cost. To this end, the main criterion will be the reduction of the weight of the product so as to put a maximum of textile in the washing machine.

Concerning the purchase cost, the complementary parameter to analyse is the life of the product, to take into consideration a purchase price/life cycle ratio (amortized purchase cost) and invest consequently. Important: the theoretical life cycle (on the technical sheet) must match the actual one, often dictated by tenders (2 to 3 years on average).

In a nutshell...

The weight and life cycle of microfiber textiles are criteria that can help make a choice based on the quality/price/profitability ratio and not only on the benefit perceived at first sight.

Only chemicals can remove bacteria

FALSE! As there are no textile standards in this area, DECITEX has decided to prove the effectiveness of its products under the Dispomop® technology by having them tested by MIDAC, according to the methodology of standard EN16615, in water cleaning. The tests results show a reduction in microbial contamination ( on staphylococcus aureus) greater than 4log, using water.

The Dispomop® technology can therefore help obtain a clean, decontaminated surface with water as the only complement to textile:

Dispomop® - disposable microfiber mop (Awarded Europropre's innovation award) | Dispomop® 3D - short life microfiber mop (patent n° 07 54564).

Facts...

A majority of French health care facilities have challenged the use of disinfection products for cleaning floors. In Scandinavian countries and in England, renowned health care facilities have been cleaned with water with microfiber mops and compare favourably with French facilities in the fight against hospital-acquired infections.

If it's more resistant it's better for the planet

NOT NECESSARILY!

Market players have been trying to outdo one another in terms of number of washes announced for long-life mops: 500, 800, 1000 washes… Sure, you can do better than that!

It is important to realise that a mop guaranteed to withstand 800 washes should hold for 6½ to 8 years of use!

Facts...

In hospitals, the equipment is renewed every 2 to 3 years on average by tender; we might as well announce 20,000 washes without taking risks as, with a rotation of 3, the actual total life cycle is 365 washes!

Learn more...

The environmental footprint is far from being limited to the theoretical or even actual life of a mop. The weight of the mop will have a significant impact on the weight of waste at the end of life, and on the water and chemical consumption in service and for laundry during its use.

Example: a 15 g mop, 4 times less resistant than a 60 g mop will have the same environmental impact at the end of its life since the weight of waste is equal. In addition, the lighter mop divides by 4, all along its use, the consumption of water and detergent in laundry (4 times more mops can be washed in each machine load).

100% microfiber is better!

TRUE for cleaning high surfaces - FALSE for floors!

This has to do with the ease of use. When the mop is at the end of a broom, it cannot be moved as easily as by hand. When used damp, a 100%-microfiber mop will closely adhere to the floor and make cleaning more tiring and painstaking. This is the so-called "scotch-tape" effect.

For a microfiber mop to be efficient while easy to move around on the floor, it must definitely be made up of one part of microfibers (the highest possible) and one part of non-microfiber threads.

Learn more...

There is certain diversity in the composition of floor mops.

You will find compositions with 50% microfibers and 50% non-microfibers, 70% / 30% or 80 % / 20%...

We can actually play with the size of the microfiber thread (Between 0.2 and 1 decitex) to maximise its presence in the finished product, but beware! 100% microfiber never means easy to use!

The thinner the thread, the more efficient!

TRUE BUT INCOMPLETE. To be correct, it should read: the thinner the thread, the more efficient it is, the less appropriate it is to clean floors (so-called "scotch-tape" effect).

The dense capillary network formed by a 0.2 decitex thread generates such an absorption effect, that a damp mop made up of these microfibers only, would be virtually impossible to move on the floor. This thread can therefore only be used if it is combined with thicker threads (>3 or 4 decitex) in large quantities (at least 50% of the mop). The result of such a mix will therefore deliver a low performance because of the low percentage of microfibers in contact with the floor.

What a cleaning product is made up of is therefore the result of a subtle compromise between efficiency and ease of use. Various parameters come into play: the size of the thread, the proportion of different threads, the distribution, the weight per sqm, the contact with the ground, absorption, chemical and heat resistance, wear...

How to make your choice...

Taking a 0.2 decitex thread as the only criterion for efficiency leads to a result that is contrary to what is expected. It is recommended to choose a mop containing a maximum of microfibers in contact with the floor even if these are larger than 0.2 decitex (between 0.5 and 0.6 decitex for example). The two criteria are then: a maximum of microfibers in contact with the floor (over 70%) combined with acceptable sliding properties. But beware! 100% microfibers does not necessarily mean easy to use!

Some microfibers scratch, others absorb!

FALSE. Any microfiber (a fibre whose size is lower than 1 decitex), due to its intrinsic properties, can both scratch (mechanical force) and absorb (capillary force) thanks to the dense capillary network formed by its threads. The thinner the threads, the higher the performance of these two properties, the more efficient the collection of dirt is. All the dirt is lifted and trapped in the textile and cannot redeposit.

Extra tip

Microfibers generally come from synthetic materials (polyester | polyamide) that develop electrostatic forces, that, when used dry, attract dust like a magnet.